Invisible Variations That Define Yield :Practical Applications of SPC in Semiconductor Manufacturing

·Process Control Methods for High Yield and Stable Volume Production:

1. What Is the Real Risk in Semiconductor Manufacturing?

In semiconductor manufacturing, the most dangerous issues are often not obvious out-of-spec events, but invisible and persistent process variations.

Wafer fabrication involves hundreds to thousands of tightly coupled process steps, each operating within extremely narrow process windows. Even a minor parameter shift can be amplified through downstream processes, eventually resulting in:

Yield degradation

Parameter distribution drift

Large-scale scrapping of high-value wafer lots

This reality determines that the semiconductor industry cannot rely on end-of-line inspection to ensure quality. Instead, it must continuously answer two critical questions during production:

Is the process stable?

Is the process still under control?

Statistical Process Control (SPC) exists precisely to address these questions and has become a foundational capability in modern semiconductor manufacturing.

2. The Role of SPC in the Semiconductor Industry

Unlike traditional manufacturing, SPC in semiconductor fabs is not merely a statistical tool used by quality departments. Instead, it serves as:

A daily monitoring method for process engineers

A key reference for equipment and process condition assessment

A critical input for yield management and production release decisions

In practice, SPC is typically integrated with MES/EAP/FDC/APC systems, forming a comprehensive process control framework that supports:

Early identification of process drift

Proactive exception handling in advance

Support process and equipment decisions

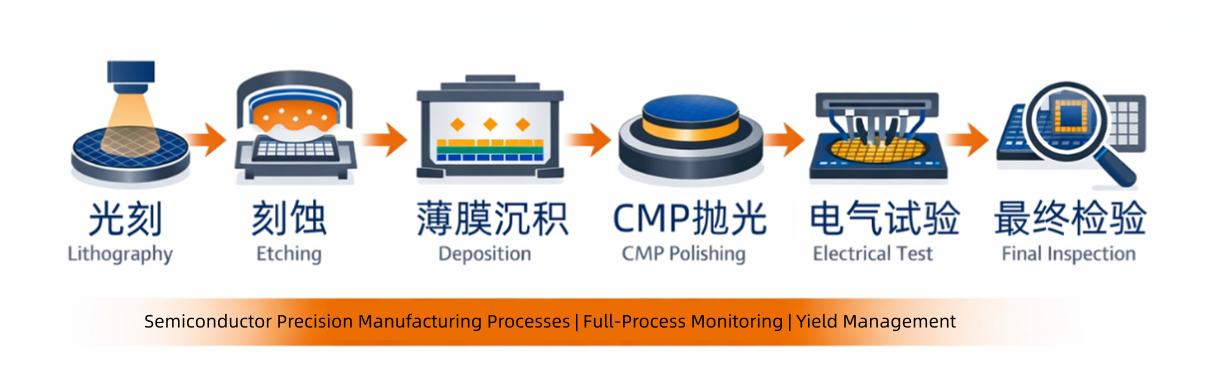

3. Typical SPC Application Scenarios in Semiconductor Manufacturing

3.1 Lithography: Core Control of Process Windows

Lithography is one of the most yield-critical steps in semiconductor manufacturing. SPC is commonly used to monitor:

Critical Dimension (CD)

Overlay

Dose

Focus

Given the extreme sensitivity of lithography parameters to yield, semiconductor fabs focus heavily on subtle trend shifts rather than obvious limit violations. Therefore, SPC applications often combine:

I-MR control charts

EWMA and CUSUM trend detection methods

to enable early detection of ”chronic loss of control“.

3.2 Etching: Ensuring Uniformity and Stability

In etching processes, SPC is primarily applied to monitor:

Etch depth

Line width variation

Within-wafer and wafer-to-wafer uniformity

Continuous SPC monitoring helps engineers identify:

Chamber condition changes

Consumable aging and contamination risks

Process parameter drift

thereby reducing the risk of batch-level excursions.

3.3 Thin Film Deposition (CVD / PVD / ALD): Consistency Management

Typical SPC monitoring parameters in deposition processes include:

Film thickness

Refractive index

Resistivity

Uniformity

SPC is used not only for single-tool stability control, but also widely applied in:

Tool matching across multiple equipment sets

Maintenance and cleaning interval optimization

3.4 CMP (Chemical Mechanical Planarization): Preventing Over-Polish and Under-Polish

CMP processes are characterized by high process noise and complex parameter coupling. SPC monitoring focuses on:

Removal rate (RR)

Surface roughness

Planarity metrics

By applying SPC, fabs can distinguish random variation from systematic drift, preventing long-term yield loss caused by cumulative deviations.

3.5 Electrical Testing and Yield Monitoring

In front-end manufacturing, SPC is applied not only to process parameters, but also extensively used for:

Monitoring key electrical characteristics

Analyzing yield trend indicators

This allows engineers to trace yield anomalies upstream to specific process steps, enabling faster root-cause identification.

4. Key Characteristics of SPC in Semiconductor Manufacturing

Compared to traditional manufacturing, semiconductor SPC exhibits distinct characteristics:

4.1 High Frequency, Small Samples, Large Data Volumes

Single-point or very small subgroup sampling

High-frequency monitoring

4.2 Complex Data Distributions

Non-normal distributions are common

Skewed and long-tailed characteristics frequently observed

As a result, practical SPC applications often require a combination of:

Data transformation methods

Trend-based control charts

Non-normal analysis strategies

4.3 Focus on Trends Rather Than Single-Point Violations

In semiconductor manufacturing, the most significant risks typically arise from:

Long-term, gradual, and continuous process drift

Therefore, the core value of SPC lies in early trend detection, rather than reacting only after parameters exceed control limits.

5. Core Value Delivered by SPC for Semiconductor Enterprises

Through systematic SPC implementation, semiconductor manufacturers can:

Detect process instability early and protect yield

Reduce the risk of scrapping high-value wafers

Support equipment maintenance and process optimization decisions

Improve consistency and stability across tools and production lines

In advanced process nodes, SPC has become a key reference for process release and stable mass production.

6. Conclusion: SPC as the “Invisible Defense Line” of Semiconductor Manufacturing

In the semiconductor industry:

Invisible variations are often the greatest risk.

SPC is not merely a set of statistical charts, but a comprehensive process control methodology designed to:

Continuously monitor process conditions

Detect abnormal trends at an early stage

Safeguard yield and stable volume production

Those who can identify process drift earlier are better positioned to protect yield—and maintain long-term competitiveness.

- What If Subgroup Sizes Are Not Fixed?

- Simple SPC 4.0 – Detailed Product Overview

- Simple SPC 4.0 Official Release

- Using data to safeguard safety: Application practices of SPC in the pharmaceutical industry

- How can risks be identified in advance in automobile manufacturing? — Sharing SPC application practices

- Innovative Practices and Applications of Web SPC Systems

- Should Manufacturing Companies Still Implement SPC Amid Economic Downturn and Poor Business Performance?

- What should we do if the customer requires the immediate implementation of SPC process control during a factory audit?

- Simple SPC has been recognized for the third time as the "2025 SPC Statistical Process Control Software of the Year" by China SoftWare Home.

- Giving SPC AI Wings: DeepSeek Enhancing Efficiency and Depth of Quality Management

- AI-Enhanced Statistical Process Control (AI-SPC): Revolutionizing Quality Management in the Era of Smart Manufacturing

- General-Purpose Artificial Intelligence Models (DeepSeek, etc.) and Statistical Process Control (SPC): A New Era of Intelligent Quality Management

- Simple SPC 2.0 released, with upgraded functions and optimized performance

- CPK and PPK: Essential Questions in Quality Interviews, Do You Truly Understand Them?

- Unilateral or Bilateral: An In-Depth Exploration of Specification Limits and Control Limits in SPC Analysis and Their Impact on Metrics

- How to Calculate Control Limits for Xbar-R and Xbar-S Control Charts in SPC Analysis and When to Use Each Chart

- Is SPC or Another Method Better for Determining Batch Consistency with Standards? A Recommended Analysis Approach

- Beyond SPC Control Charts: Lesser-Known but Effective Quality Analysis Tools

- SPC is the most accessible, effective, and performance-demonstrating analytical tool in the manufacturing industry.

- How to Quickly Identify Hidden Correlations Between Test Items Using the SPC System?